In the world of energy storage, precision is capital. Yet, standard Battery Management Systems (BMS) suffer from a critical flaw: Sensor Drift. Traditionally, to get higher precision, engineers add expensive current sensors. But at Bangsaen AI, we asked: "Can we replace hardware with better math?"

Standard algorithms like Coulomb Counting ($\int I dt$) work on paper, but in reality, they integrate noise. This leads to "Drift"—where the estimated battery level slowly diverges from reality, like a ship losing its compass at sea.

1. The Problem: The Drift of Coulomb Counting

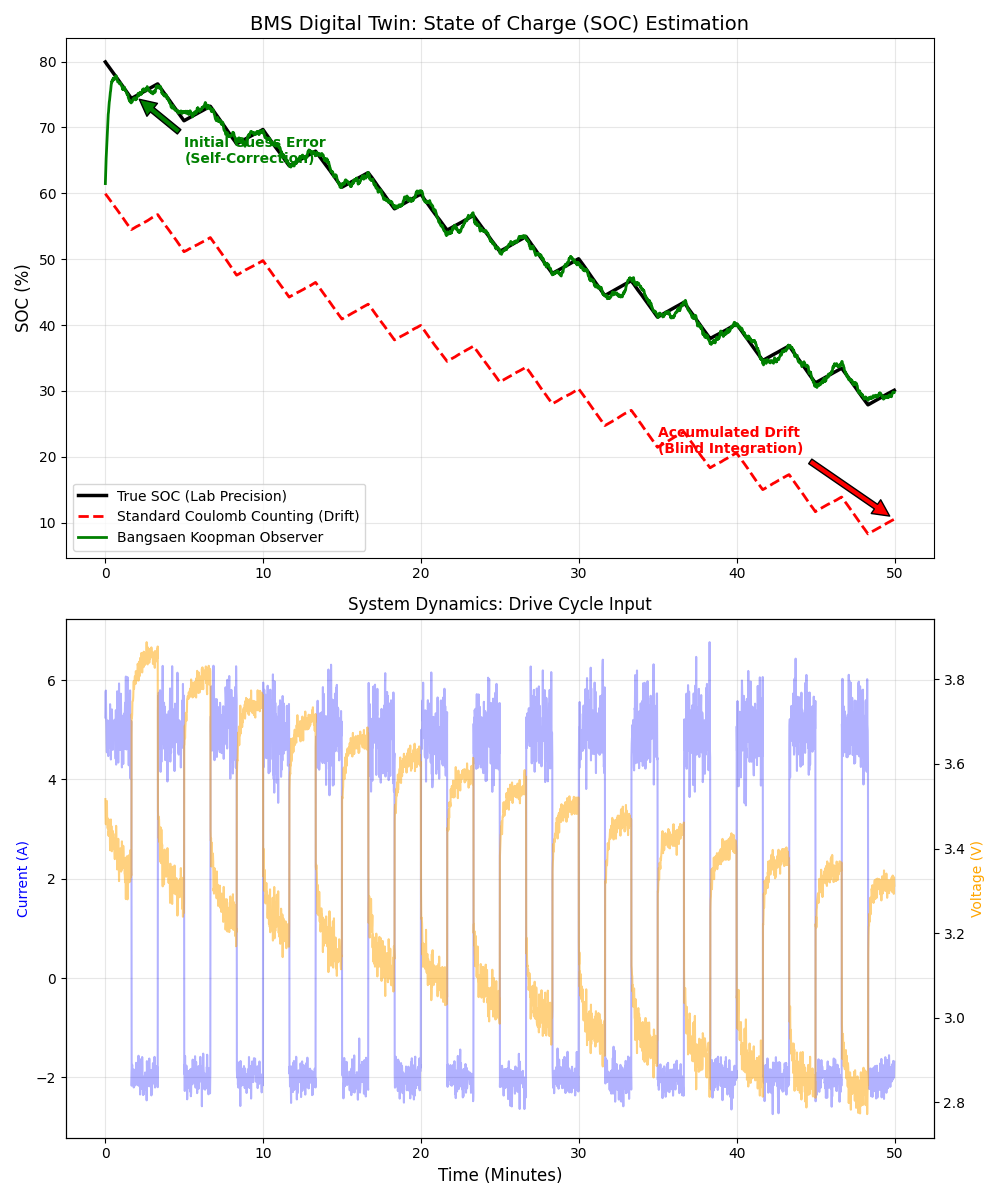

We ran a comparison on a dynamic drive cycle. The red line in the graph below represents the standard algorithm. Notice how it blindly integrates the current, slowly drifting away from the True SOC (State of Charge) until the data becomes useless.

2. The Solution: Koopman Operator on Silicon

Instead of trusting the sensor blindly, we implemented a Koopman Operator approach. This allows us to lift the non-linear dynamics of the battery chemistry into a linear space where we can apply standard control theory.

"The 'Soft Sensor' treats noise as noise, not data. Even with a wrong initial guess, the algorithm snaps back to the true value within seconds (Self-Correction)."

3. Lab-Grade Precision on a $2 Chip

The most significant breakthrough isn't just the math—it's the implementation. We successfully compressed these complex linear algebra operations to run on a standard ESP32 microcontroller.

This proves that advanced Embedded AI is accessible. You don't need industrial-grade PCs to achieve Zero Drift; you just need a better model of the physics.